textblock default title

»An iridescent leather sample was submitted. The aim is to determine what the coating was made of and how it was produced. The question was answered, and the process was [...] sold.«

Annual Report of the Control Laboratory, 1926

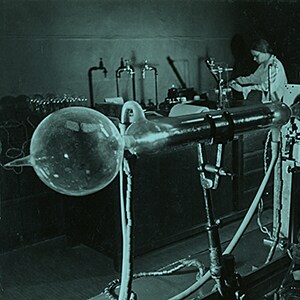

In the 1920s, the company increasingly turns its attention to new processes and products outside its core pharmaceutical business. To this end, the company cultivates contacts in a wide variety of industrial sectors, such as the cosmetics industry and printing ink factories. The effect of the iridescent layers is already being investigated in the laboratories at this time. »Glass, stones for wall coverings, paper and leather« – customers want to visually enhance their products or simply know how this effect is achieved. The latter leads to the sale of a corresponding process to the leather industry.

The shine is achieved by »bismuth oxychloride«, which is »continuously tested by the control laboratory [...] for its suitability for this purpose«. A special quality is required by customers in order to be able to produce the gloss »without smearing«, as a report from 1929 shows.

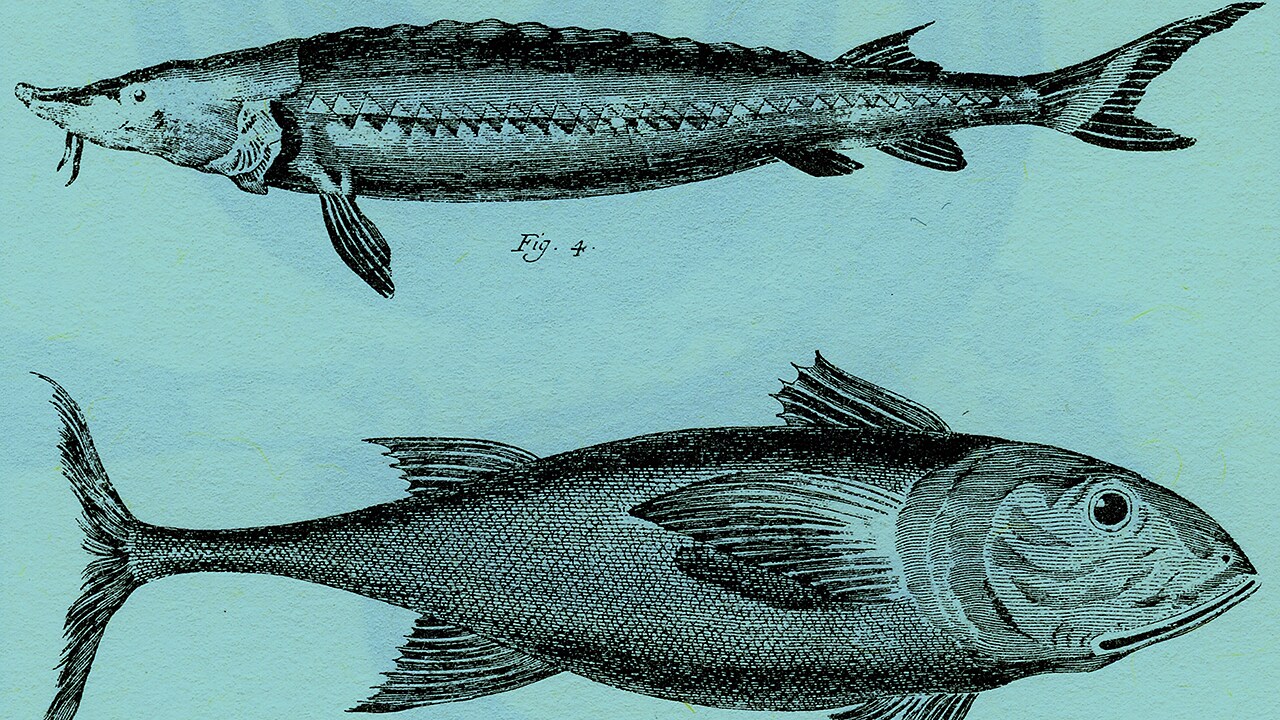

This particular splendor has been sought after for centuries. In the mid-17th century, fish silver was the decisive aid, a delicate, shiny powder which, after cleaning small fish, was deposited in the water as sediment – the »essence d’orient«. However, it took 18,000 to 20,000 fish to produce 500 grams of silver luster. In the following centuries, iridescent pigments became a necessity in fashion circles for a wide variety of applications. For example, the shiny platelets of the bismuth compound are used in cosmetic powders under the name »Blanc de Perle«. For buttons, this is intended to imitate the natural mother-of-pearl effect.

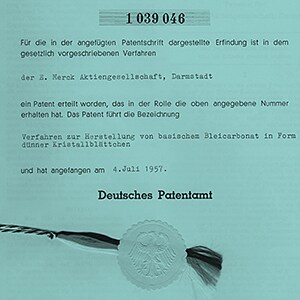

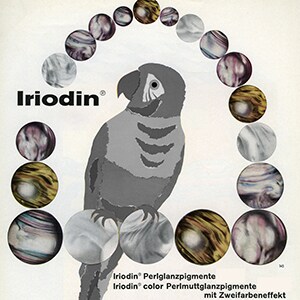

In 1933, the company commences initial attempts in its main laboratory to manufacture various iridescent substances »which do not yet fully satisfy the demand of interested customers«. Two years later, the production of an iridescent agent based on lead phosphate begins. Yet the substances are problematic. The challenge for the future is to search for substances that are not poisonous, easy to process and nevertheless »magnificent«. Systematic research begins in the 1950s. In 1959, the production of Iriodin, a pearlescent pigment based on basic lead carbonate, commences in Gernsheim, Germany.

A breakthrough was achieved in 1970. Extensive work shows that the white pigment titanium dioxide would be an ideal pearlescent pigment. However, production in flake form does not succeed. The search for a suitable substrate to which the pigment could be applied in a thin layer leads to the naturally occurring mineral mica. The coating of the material creates a superb interference pigment.

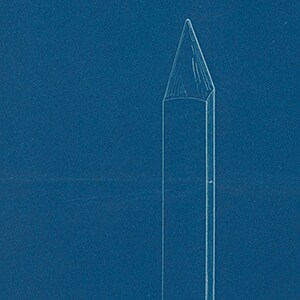

In the early 20th century, work with pigments becomes an increasingly diverse topic at the company. This includes the drawing pen as a possible application for the new fluorescent colors as well as Cyanotypin for the »blueprint industry« and its fully automated photocopiers.

The first references to work on iridescent preparations in the 1920s can be found in reports from the control laboratory, guarantor for the quality of the products from company manufacturing plants. The research laboratories newly created in the early 1930s are also available for further research work.

The patent on the process for the production of basic lead carbonate in the form of »thin crystal flakes« is the basis for starting production of Iriodin as a pearlescent pigment. Plastics and coatings are among the areas of application.