»And it is wonderful when things then workin the laboratory as intended.«

Hans Kammer, the last glassblower at Merck KGaA, Darmstadt, Germany, 2001

The film »Tradition und Leistung« (Tradition and Achievement) premieres in 1961. Approximately 27 minutes long, it offers a look at production and research within the company. At the interface between the laboratory and production, the glassblowing workshop plays an important role. By crafting specialized custom equipment, this unit paves the way from laboratory to the commercial scale necessary for production.

In the 1950s, the glassblowers are located on the second story of the »Science« building, thus putting them in the immediate vicinity of the research laboratories. The manufacturing units make use of their expertise as well, followed later on by company subsidiaries outside Germany. The glassblowers are always called upon when, on the route from the idea to the product, the items in the catalogue are insufficient to the task.

The pieces created primarily include »chillers, distillation equipment, specialized equipment for microanalysis and pharmacology, and glass containers for all sorts of chemicals, fermentation processes and bacteriological procedures«. In crafting this equipment, not only the shape matters, but also the type of glass because the finished pieces must withstand specific temperature and pressure levels. In the mid-1950s, seven glassblowers are responsible for meeting the scientists’ numerous wishes. The last glassblower retires in 2001; as with many other handicrafts of a technical nature, external suppliers will be contracted to meet the company’s needs.

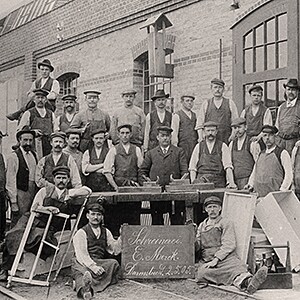

At the turn of the 20th century, a number of skilled handicrafts are represented at the company. As the company pharmacy transitions to an industrial company in the 19th century, these positions become increasingly important. In 1900, 85 out of nearly 1,000 employees are assigned to the workshops and energy generation unit, including assemblers, coopers, saddlers, coppersmiths, and joiners. Their tasks range from maintaining or building technical equipment to manufacturing packaging and building custom solutions for special production requirements.

A record from the 1920s mentions a very special order for a carpenter. The thick trunks of the quassia tree must be processed in order to extract quassin. The planer machine must be operated by the experienced craftsman from the workshop. In the 1950s, the workshops develop and construct a copper wire winding machine for use in the production of highly pure copper oxide. This requires a spindle that is as loosely wound as possible to ensure the even flow of hot air. In a special furnace heated to 1,000°C, these spindles are transformed into copper(I)oxide. This company-built machine works so well that it remains in service until 2006.

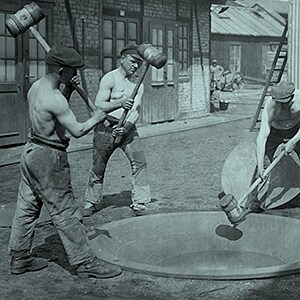

Muscular strength, finesse and a great deal of expertise are essential to metalworking. In the 1920s and 1930s, not only boiler ends and coil coolers are forged at the company. Welders spend their days making repairs to production equipment as well as working in the boilershop.

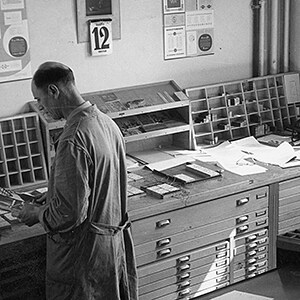

Company print shop, 1956: The templates go from the machine compositor to the making-up room for page layout. Photos are inserted and manually typeset tables added. The documents are printedin the pressroom. Each printing plate contains four pages, with special preparations made for photos.

In 1905, carpenters are needed everywhere, with their repertoire including both filing cabinets and wooden shipping crates. In the mid-1950s, the company tailor-shop performs approximately 80,000 individual repairs. For the telephone system installed in 1963, company technicians change the exchange lines to a switchboard.