»The bacteria develop particularly rapidly during thunderstorms. In winter, it was necessary several times [...] to prompt the process with rotten cheese.«

Report from the Technical Fermentation Room, 1920

The nature of the fermentation process was the topic of a bitter dispute around 1850. From a chemical-mechanist perspective, Justus von Liebig vehemently advocates in leading publications the position that fermentation is purely anorganic chemical process. Louis Pasteur, who is a proponent of the theory of Vitalism, describes the process as being dependent on the activity of living microbes. Liebig commands authority, and so his theory is at first accepted – until Pasteur discovers the bacterium responsible for lactic acid fermentation and refutes the concept of it being a purely chemical process. When Eduard Buchner shows in 1897 that cell-free extracts of yeast could also ferment sugar by means of enzymes, it becomes possible to unify the theories to give rise to modern biochemistry.

However, the statement »Fermentation is enzyme chemistry« has far-reaching consequences. In chemistry, fermentation research becomes more scientific. But where is the associated biology? It remains within commercial organizations – fruitful for their industrial practice, but irrelevant for academia. For a long time, biotechnology is regarded as merely controlled by trial and error, without any scientific basis.

Biotechnological processes are less exotic for manufacturing companies with pharmacy origins such as Merck KGaA, Darmstadt, Germany, than for companies with a tradition of tar dyes. Biotechnology finds its way into production, after all the search for materia medica had always been conducted by means of »intuitive speculation« as well. Initial experiences are also made with lactic acid. Acidum lacticum is traditionally prepared in the pharmacy by inoculating a sugar solution with sour milk. This cannot even be considered for large batches. Around 1890, an effective methodis found: Lactobacilli are used to convert the carbohydrates from whey into nutrient solution in an anaerobic process. Sensibly, this is performed in a dairy in the Allgäu, an agricultural region of southern Germany. The procedure can be well-controlled using one’s intuition – and provides useful experiences.

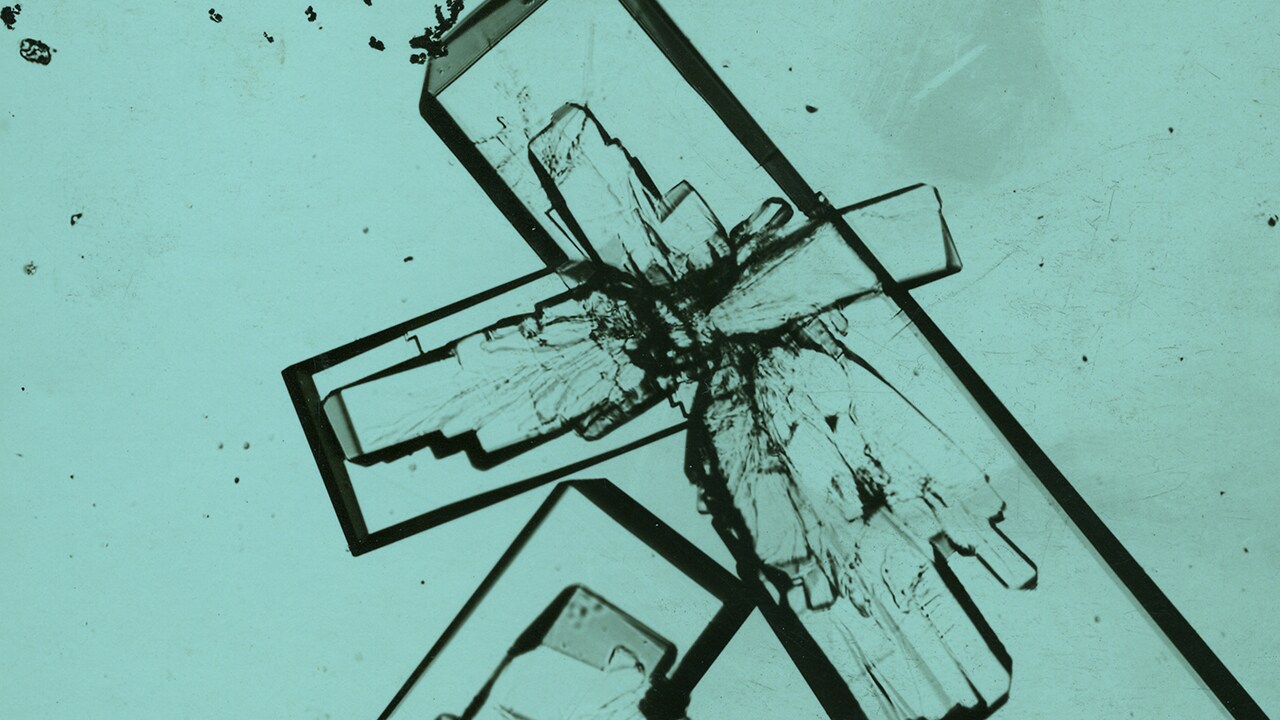

In 1934, the structure of ascorbic acid is elucidated. the company offers »vitamin C« under the brand name Cebion. But extraction is work-intensive. Only extraction from gladioli, which have to be cultivated for this purpose in Darmstadt, delivers decent results. Upon successful synthesis »according to Reichstein« in Switzerland, the company is also able to make use of it. Here, a biotechnological step is used in the chemical process to solve a complex problem. Using submerged fermentation in large-scale production is no trivial matter. Nevertheless, efforts already succeed in 1940, with monthly production output amounting to five metric tons of ascorbic acid.

Detailed knowledge of molecular biology and the technological possibilities become the key to developing many important medicines.

»In 1933, the firm Merck in Darmstadt successfully produced pure crystallinel-ascorbic acid in large quantities frompeppers. During systematic research, the company discovers that gladioli contain three times more ascorbic acid than peppers and ten times more than oranges«, reports the »Textbook of Biological Remedies« in 1938.

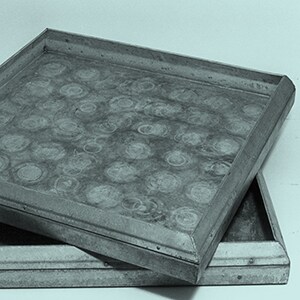

In vitamin C synthesis »according to Reichstein«, scientists use »the bacterial oxidation of D-sorbitol to L-sorbose«; named after the chemist Tadeus Reichstein. Until 1939, E. Merck, Darmstadt, Germany, produces L-sorbose with surface cultures in about 1,000 aluminum dishes for a period of multiple weeks until the acetic acid bacteria metabolize D-sorbitol.

As of 1939, the required microorganism cultures are pre-cultivated in 900-liter steel cylinders. New strains of bacteria are regularly collected, isolated, tested and multiplied.