Thin Films

Thin films create the intricate layers essential for enhancing computational power and energy efficiency in complex chip structures, serving a fundamental role in modern semiconductor technology.

next-generation semiconductor applications

Thin films layers range from a few atoms to several microns in thickness. As we reach the physical limits of traditional scaling, innovations in thin films are vital for enabling advanced architectures like Gate-All-Around (GAA) transistors and 3D structures, enhancing both computational power and energy efficiency.

What we offer

As a leading player in atomic layer deposition (ALD), chemical vapor deposition (CVD), and spin-on dielectrics, we address challenges including complex three-dimensional architectures and electrical performance, ensuring next-generation devices achieve optimal performance.

Our broad thin film Portfolio

We offer novel materials and tailored solutions with one of the broadest portfolios in the industry, including: ALD/CVD metals, Dielectrics, Spin-on dielectrics, and provide excellent deposition processes materials.

Elevate your innovations with our vast portfolio

| Organometallics (CVD and ALD) | Organosilanes (PECVD, ALD, and FCVD) | Spin-on Dielectrics | |

|---|---|---|---|

Existing Products:

New Products:

|

Existing Products:

New Products:

|

Existing Products:

|

Capabilities

We deliver tailored solutions, quickly and precisely that meet the specific process and roadmap requirements of our customers. This enables us to deliver breakthroughs in deposition technology. Our approach leverages advanced data analytics, stringent quality controls, film deposition and metrology capabilities, ensuring that each solution is not only customized but also reliable and effective.

- We work with our customers and OEM partners, rapidly accelerating unique, innovative material solutions that address complex integration challenges.

- We build upon a collaborative and innovative R&D approach to accelerate prototyping and safeguarding of critical molecules to achieve superior device performance and integration efficiency.

- Our innovations enable the industry roadmap – improving gate control, reducing leakage, and enhancing thermal stability.

Partnerships

We closely collaborate with our Delivery System and Services (DS&S) team, integrating cutting-edge container and delivery solutions like solid-source vapor delivery that ensure the availability of critical molecules while maintaining the highest and most consistent quality. We empower our customers to achieve superior device performance and integration efficiency.

Our Intermolecular® team enhances our capabilities through rapid prototyping and validation of new materials, ensuring faster time-to-market and enabling technological breakthroughs.

Through our M4Ward™ program, we help many of the world’s biggest tech companies stretch the boundaries of science and technology, providing collaborative innovation that accelerates the development of customized materials and optimal solutions for advanced technology nodes.

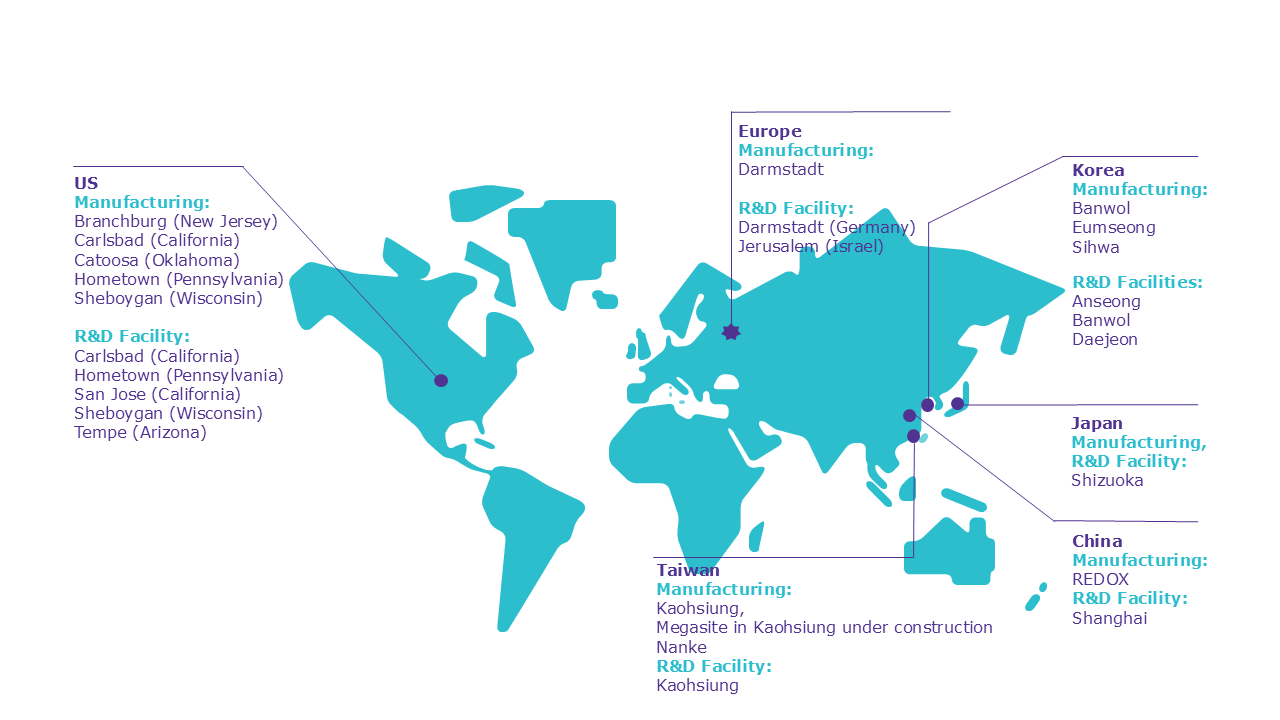

Our global facilities and localized supply chain provide supply robustness and flexibility.

Innovations For Tomorrow

Our Thin Film portfolio supports current advancements and paves the way for future breakthroughs. As we shrink to 3nm and below, the increasing variability in FinFET devices necessitates a shift to Gate-All-Around (GAA) architecture, which our Thin Films business is uniquely positioned to enable. We leverage our expertise in precise material deposition to create the highly conformal coatings required for GAA designs.

We pair our Materials Intelligence™ Solutions with data analytics to drive next generation applications, such as new transistor architecture, 3D device stacking, future interconnects and advanced packaging.

Find the right material

How can we help you? Contact us if you have a tech question, if you are looking for a tech document or need a quote or sample.

We utilize global facilities and localized supply chain to ensure robustness and flexibility.